Nachweislich sind mindestens 70 % aller Störungen in einem Hydrauliksystem auf Verunreinigung und Alterserscheinungen des Öls zurückzuführen.

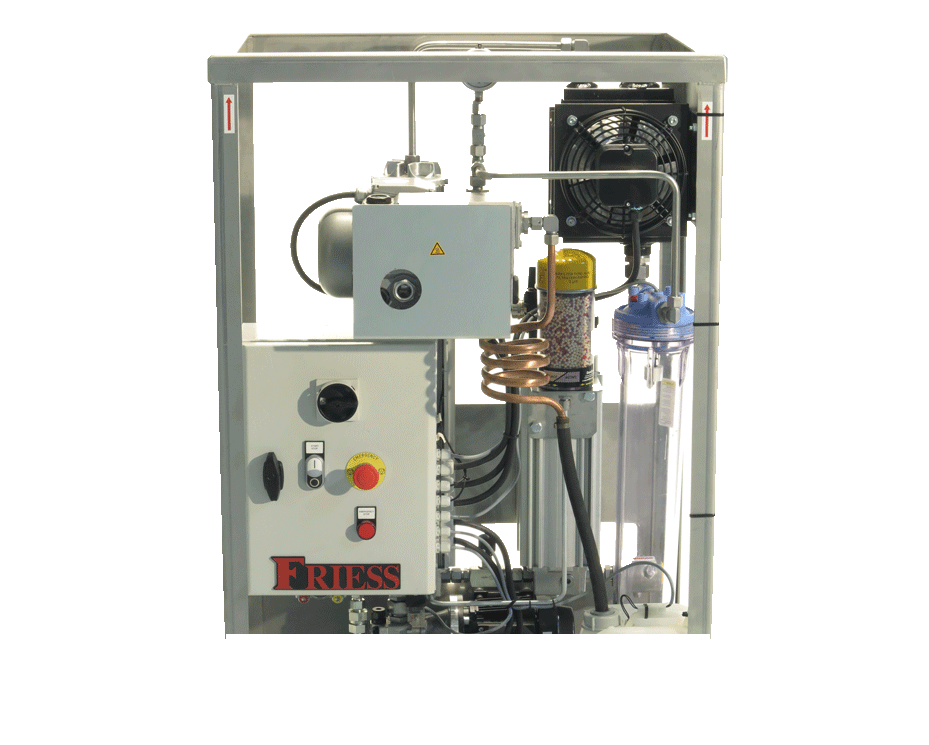

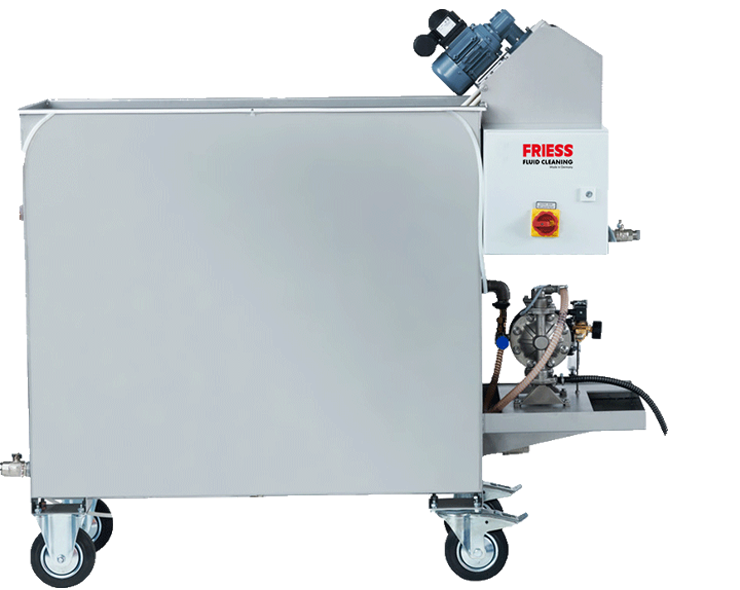

FRIESS ist Ihr Experte, wenn es um effektive Kostenersparnis durch nachhaltige Reinigung Ihrer Prozessflüssigkeiten und die Einhaltung wichtiger Normen und Vorschriften geht.

FRIESS ist Fluid Cleaning Made in Germany. Dazu entwickeln, konstruieren und fertigen wir Geräte und Anlagen, mit denen Sie Ihre anfallenden Prozessflüssigkeiten reinigen und instand halten.

Den Ölverbrauch um bis zu 90 % reduzieren und dabei die Umwelt schonen. Prozessflüssigkeiten, egal welcher Art, können deutlich länger genutzt werden. Durch die Entfernung kleinster Partikel und Harze wird die Lebensdauer von Maschinen und Werkzeugen stark erhöht.

Bei uns finden Sie innovative Lösungen, die Ihre Betriebskosten minimieren und gleichzeitig die Produktivität Ihres Unternehmens steigern. Passend zu den diversen Bedürfnissen unserer Kunden bieten wir sechs Produktlinien an: Ölskimmer, Magnetfilter und elektrostatische Ölreinigungsanlagen sowie Systeme zur Abwasseraufbereitung, Ölentwässerung und Ölabscheidung.

Mehr erfahren

Herr Oliver Benneck

Böttgerstr. 2

40789 Monheim am Rhein

Tel: (0 21 73) 5 20 11 oder 5 20 12

Fax: (0 21 73) 3 33 74

E-Mail: post@friess.info

Werksvertretung Nordrhein-Westfalen

Werksvertretung Hessen / Rheinland-Pfalz / Saarland

Herr René Brassat

Châtillonweg 25

23909 Ratzeburg

Tel: (04541) 83059-0

Fax: (04541) 83059-60

E-Mail: rene.brassat@otto-warncke.de

Internet: www.otto-warncke.de

Werksvertretung Nord für die Produkte: Ölskimmer und Magnetfilter

Wörnitzstrasse 117

90449 Nürnberg

Tel: (0911) 6 70 94 – 0

Fax: (0911) 6 70 94 – 60

E-Mail: nuernberg@berner-straller.de

Internet: www.berner-straller.de

Werksvertretung Bayern

Herr Mario Krkač

Kapuzinerweg 10

70374 Stuttgart

Tel: (07 11) 95 39 06-24

Fax: (07 11) 95 39 06-911

E-Mail: vertrieb@is-zubehoer.de

Internet: www.is-zubehoer.de

Werksvertretung Baden-Württemberg

Herr Martin Schuhmann

Charlottenbrunner Str. 6

14193 Berlin

Tel: (0 30) 71 58 100 – 6

Fax: (0 30) 71 58 100 – 8

Mobil: (0172) 31 90 196

E-Mail: mschuhmann@schuhmann-partner.de

Internet: www.schuhmann-partner.de

Werksvertretung Ost

Optical Valley International Building B510

Guandongyan Rd. No.2-2

Donghu New & High-tech Industrial Development Zone

CN-430074 Wuhan city, Hubei province

Tel: +86-27-87490195

Fax: +86-27-87490193

E-Mail: mail@oilskim-china.com

Internet: www.friess.cn

Herr Kari Luhtala

Wolffintie 36 M10

FI-65200 Vaasa

Tel: +358 20 7 459 660

Fax: +358 20 7 459 667

E-Mail: kari.luhtala@fuchs.com

Internet: www.fuchs.com/fi

Produkte: Ölskimmer und Magnetfilter

Herr Kalle Kinnari

Kärkikuja 3

FI-01740 Vantaa

Tel:: +358-10-8345-500

Fax: +358-10-8345-501

E-Mail: Kalle.Kinnari@masino.fi

Internet: www.masino.fi

Produkt: Elektrostatische Ölreinigung

Herr Aguera

31 ave. des lacs

FR-74950 Scionzier

Tel: +33-450183027

Fax: +33-450183028

E-Mail: md@mecadiffusion.net

Internet: www.mecadiffusion.com

Herr Themos Lykiardopoulos

Orfanidou 18

GR-111 41 Athens

Tel: +30 21 02 28 22 12

Fax: +30 21 02 02 55 14

E-Mail: info@stseurope.com

Internet: www.stseurope.com

John Wilson / Dan Norman

Unit 43, Equinox South Business Centre, Bradley Stoke

GB-BS32 4QL Bristol

Tel:+44-1792-277290

Fax: +44-1792-797707

E-Mail: john.wilson@amiad.com / dann@amiad.com

Internet: www.amiad.com

Nick Foster

Wakefield WF2 7HZ

Phone: +44 (0)113 328 0330

Email: sales(at)friess.co.uk

Web: www.friess.co.uk

Herr Ajinkya Kelkar

Plot No. 7, Gat No. 281/1, Kasar Amboli

Tal. Mulshi

IN-412 111 Dist. Pune / Maharashtra, Code: 27

Tel: +91 7350003958

E-Mail: ifs@innovationfilter.com

Internet: www.innovationfilter.com

Herr Ivan Partono

E-Mail: ip@indo-europetrading.com

Tel: +31-692637116

Internet: indo-europetrading.com

Herr G. Cappella / Herr R. Pagano / Herr G. Tanzi

Via Como, 69-A

IT-20031 Cesano Maderno (MI)

Tel: +39 03 62 57 51 54

Fax: +39 03 62 57 50 91

E-Mail: info@sepra.it

Internet: www.sepra.it

Herr Yuya Shimura

1-4-22 Yaesu Chuo-ku

JP-103-8680 Tokyo

Tel: +81-3-3278-6142

Fax: +81-3-3278-6147

E-Mail: shimura.yuya@moritani.co.jp

Internet: www.moritani.co.jp

Herr Vitaly Alexeev

Aptekarskij prospekt, 6 korpus A7

RU-197022 St.-Petersburg

Tel: +78 812 715 54 27

Fax: +78 812 740 76 37

E-Mail: nepspb@inbox.ru

Internet: www.nepspb.ru

Herr Xteven Teoh Hoe Seong

21, Jalan MJ 14

MY-47100 Puchong, Selangor

Tel: +60 3 80662496

Fax: +60 3 80626172

E-Mail: sales@xtstech.com

Internet: www.xtstech.com

Herr Oliver Benneck

Böttgerstr. 2

40789 Monheim am Rhein

Tel: (0 21 73) 5 20 11 oder 5 20 12

Fax: (0 21 73) 3 33 74

E-Mail: post@friess.info

ul. Krasickiego 44

PL-97-500 Radomsko

Kierownik Działu Filtracji / Filtration Department Manager:

Magdalena Pokrzywa

Mobil: +48 500 143 213

Pokrzywa@imponar.pl

Miłosz Gieroń

Doradca Techniczno-Handlowy/ Technical Sales Advisor

+48 500 143 125

Gieron@imponar.pl

Tel: +48 44 68 21 44 4

Fax: +48 44 68 20 82 0

E-Mail: imponar@imponar.pl

Internet: www.imponar.pl

Herr Carlos Oliveira / Herr Antonio Rodrigues

Estrada da Ponte de Antanhol, Lote A

PT-3041-575 Coimbra

Tel: +35 12 39 43 73 36

Fax: +35 12 39 43 86 19

E-Mail: friess.iberia@ventilaqua.com

Internet: www.ventilaqua.com

Herr Viktor Pachiu

256 Basarabia Blvd.

RO-73429 Bucharest-3

Tel: +40 21 2 55 10 81

Fax: +40 21 2 55 10 31

E-Mail: romarc@romarc.ro

Herr Johan Sandvall

Islinge Hamnväg 9

SE-18134 Lidingö

Tel: +46 87 67 03 40

Fax: +46 87 67 03 43

E-Mail: info@sandvall.se

Internet: www.sandvall.de

Herr Robert Peteri

Stensnäsvägen 4

SE-713 32 Nora

Tel: +46-587-15100

Fax: +46-587-15125

E-Mail: Robert@acmaskin.se

Internet: www.acmaskin.se

Herr Ulrich Ritter

Römerstraße West 49

CH-3296 Arch

Tel: +41 32 37 73 52 2

Fax: +41 32 37 73 52 4

E-Mail: info@rimann-ag.ch

Internet: www.rimann-ag.ch

Herr Xteven Teoh Hoe Seong

21, Jalan MJ 14

MY-47100 Puchong, Selangor

Tel: +60 3 80662496

Fax: +60 3 80626172

E-Mail: sales@xtstech.com

Internet: www.xtstech.com

Herr Tomáš Kara-Ivanský

Sepekov 381

CZ-398 51 Sepekov

Tel: +42 07 37 18 19 49

Tel: +42 06 04 26 91 71

Fax: +42 02 72 77 24 00

E-Mail: info@4TEK.eu

Internet: www.4TEK.eu

Herr Carlos Oliveira / Herr Antonio Rodrigues

Estrada da Ponte de Antanhol, Lote A

PT-3041-575 Coimbra

Tel: +35 12 39 43 73 36

Fax: +35 12 39 43 86 19

E-Mail: friess.iberia@ventilaqua.com

Internet: www.ventilaqua.com

Herr Allex Cheng

4F, N.O. 127, Sec. 3, Ren Ai Rd., Da An Dist.

TW-10656 Taipei City

Tel: +8 86-2-27 11-58 29

Fax: +8 86-2-27 11-61 39

E-Mail: allex@wellsuccesseng.com

Herr Ratthawit Kij-areechote

104/2 Sukhaphiban 2 Road, Prawet

TH-10250 Bangkok

Tel: 0066-2329-2001

Fax: 0066-2329-2154

E-Mail: ratthawit@mte.co.th

Internet: www.mte.co.th

Herr Tomáš Kara-Ivanský

Sepekov 381

CZ-398 51 Sepekov

Tel: +42 07 37 18 19 49

Tel: +42 06 04 26 91 71

Fax: +42 02 72 77 24 00

E-Mail: info@4TEK.eu

Internet: www.4TEK.eu

Frau Birsen Alpartun

Büyükdere Cad.,Yapi Kredi Plaza, “C” Blok Kat: 18

TR-34330 Levent, Istanbul

Tel: +90-212-2783281

Fax: +90-212-2782884

E-Mail: b.alpartun@flogaz.com

Internet: www.flogaz.com.tr

Frau Tatyana Kuzmenko

Borispolskaja str. 7, Room 225

UA-02099 Kiev

Tel: +380-44-3695177

E-Mail: tatyana@77lubricants.com.ua

Internet: www.tansel.com.ua

Herr Robert Jakatics

Zsolt u. 8/A

HU-1016 Budapest

Tel: +36-1-225-8888

Fax: +36-36-1-225-8685

E-Mail: robert.jakatics@hskft.hu

Internet: www.buvar-szivattyu.hu

Hier finden Sie die Kontaktdaten unserer Händler in Ihrer Nähe.

Nachweislich sind mindestens 70 % aller Störungen in einem Hydrauliksystem auf Verunreinigung und Alterserscheinungen des Öls zurückzuführen.

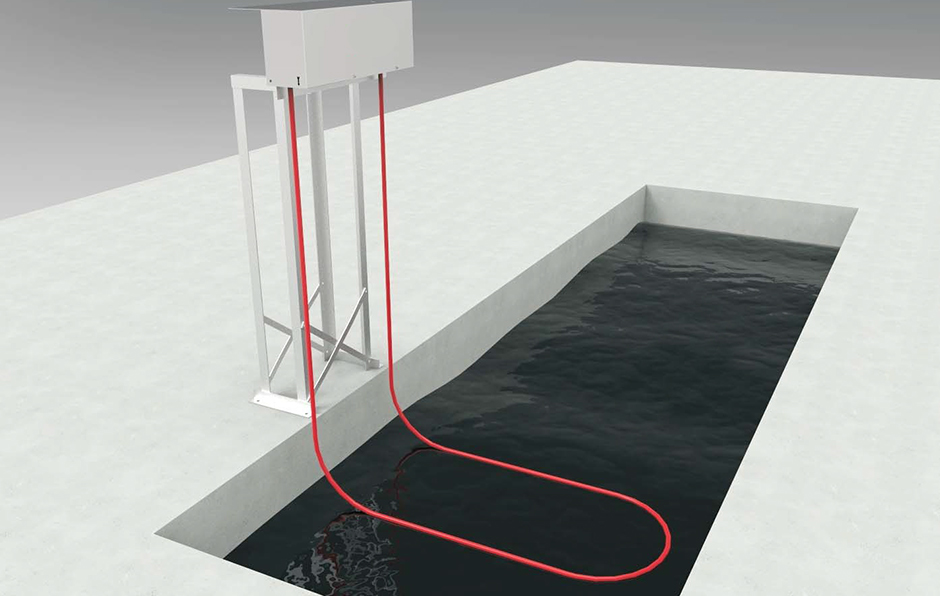

Das zeigt die vielseitigen Einsatzmöglichkeiten der FRIESS Ölskimmer, insbesondere der leistungsstarke S 100, der für jede Beckenform- und Größe anpasst werden kann.

Die gängige Abkürzung von Kühlschmiermitteln, bzw. Kühlschmierstoffen ist KSS. Umgangssprachlich werden auch Bezeichnungen wie Schleifwasser oder Bohrwasser verwendet.

Eines der größten Stahlwerke in der Türkei nutzte in einem Absetzbecken für Kühlwasser einer Kaltwalzanlage einen Ölskimmer eines anderen Herstellers.

In einem chemischen Betrieb werden Palmöle zu Vorprodukten in der Waschmittelherstellung verarbeitet. Die Abwasserqualität nicht mehr den Anforderungen.

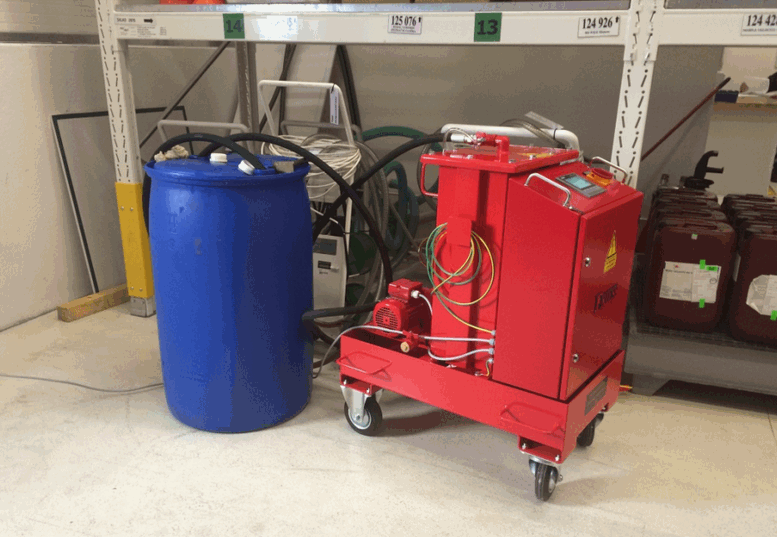

Ein europäischer Automobilhersteller betreibt insgesamt drei Werke für die Fertigung von Getrieben. Es werden. 10.000 l Hydrauliköl in verschiedenen Maschinen eingesetzt.

Aufgrund der sehr hohen Staubbelastung im gesamten Werk verschmutzt das eingesetzte Hydrauliköl relativ schnell.

Aufgrund der zunehmenden Verschmutzung des Hydrauliköls kam es zu Ausfällen bei den Hydraulikmotoren. Teilweise war wöchentlich ein Hydromotor defekt.

Bedingt durch bisherige negative Erfahrungen mit Feinfiltersystemen war man zunächst äußerst skeptisch, ob eine elektrostatische Ölreinigung eine Verbesserung bringt.

Wenn das Öl seine Aufgaben nicht mehr korrekt erfüllt, wird die Maschine schneller verschleißen und schließlich ausfallen.

Bei einem Aluminiumwerk in Westfalen sind zwei hydraulische Pressen mit einem Ölvolumen von jeweils ca. 12.000 l Hydrauliköl HLP 46 im Einsatz.

Bei einer genauen Fehleranalyse wurde festgestellt, dass der Schmutzanteil im Hydrauliköl deutlich höher war, als für die präzise Servotechnik zulässig.

Nach dem Waschvorgang werden die Teile mit Hydrauliköl Typ HLP 46 auf Dichtigkeit überprüft. Für diese Überprüfung gibt es insgesamt drei Prüfstände.

Es gelangen Staubpartikel sowohl über den Luftfilter als auch über die Zylinderdichtungen in das Hydrauliköl.

Freiformschmiedebetrieb werden verschiedene Schmiedeprodukte gefertigt. Im Hydraulikölkreislauf sind 120000 Liter vorhanden. Ein Ölwechsel verursacht erhebliche Kosten.

Befall von gesundheitsgefährdendem Schimmel oder Mikroorganismen wie Bakterien im Kühlschmierstoff erkennen und Maßnahmen ergreifen.

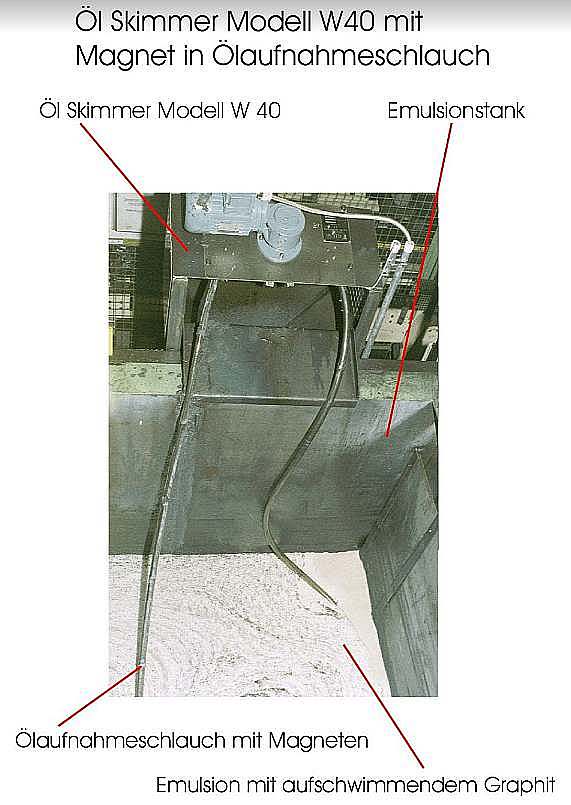

Vom Anlagenbauer wurde ein System gesucht, das die aufschwimmende Ölschicht, bestehend aus Schmieröl, Hydrauliköl, Graphit und Sinter, zuverlässig, vollautomatisch ...

Öl in einem Hydrauliksystem sollte regelmäßig auf seine Qualität hin geprüft werden. Dies geschieht entweder im firmeneigenen Labor oder bei einem externen Dienstleister.

Ein Unternehmen stellt Räder für Eisenbahnen her. Nach dem Schmieden müssen diese noch nachbearbeitet werden. Dies passiert in großen Bearbeitungszentren. Drei von diesen

In einem Stahlwerk wird das Kühlwasser sehr stark durch verschiedene austretende Öle verunreinigt.

In einem Stahlwerk sind in einer Halle zwei große Hydrauliksysteme eingesetzt.

Jede Maschine verfügt über einen separaten Vorratstank mit Filteranlage für den eingesetzten Kühlschmierstoff.

Im Stammwerk eines mittelständischen Kunststoffverarbeiters sollten die Kosten für den Wechsel von Hydrauliköl an den Spritzgussmaschinen reduziert werden.

In Druckgussbetrieben werden die Formen mit hochtemperaturfesten Trennmitteln eingesprüht, um ein einwandfreies Entformen der Gussteile zu ermöglichen.

An einem Längsklärbecken in einem Stahlwerk war ein Ölskimmer mit Mopkordel eingesetzt.

FRIESS Ölskimmer werden hauptsächlich bei vier Anwendungsgebieten eingesetzt. Hier erfahren Sie mehr über die Einsatzmöglichkeiten.

Durch die Drehbewegung des Ölaufnahmeschlauches wird die gesamte Oberfläche ölfrei gehalten.

Zur Reinigung von Kühlwasser in Stahlwerken wird üblicherweise eine Kombination aus Sinterbrunnen, Längsklärbecken und anschließendem Kiesfilter eingesetzt.

Bei der Herstellung von Biodiesel aus Rapsöl passiert es, dass das Rohöl als auch das

Endprodukt ins Abwassersystem gerät.

Nach dem Abschreckprozess im Ölbad müssen die Teile für die weitere Bearbeitung gewaschen werden.

In einem Motorenwerk eines großen japanischen Autoherstellers in China werden zwei Honmaschinen zur Bearbeitung von Motorengehäusen eingesetzt.

Bei einem Hersteller von gewalzten Stahlprofilen werden ca. 4000l Emulsion zur Schmierung und Kühlung der Walzen eingesetzt.

Bei einem großen Automobilhersteller werden Druckgussmaschinen zur Fertigung von Motoren und Getriebebauteilen eingesetzt.

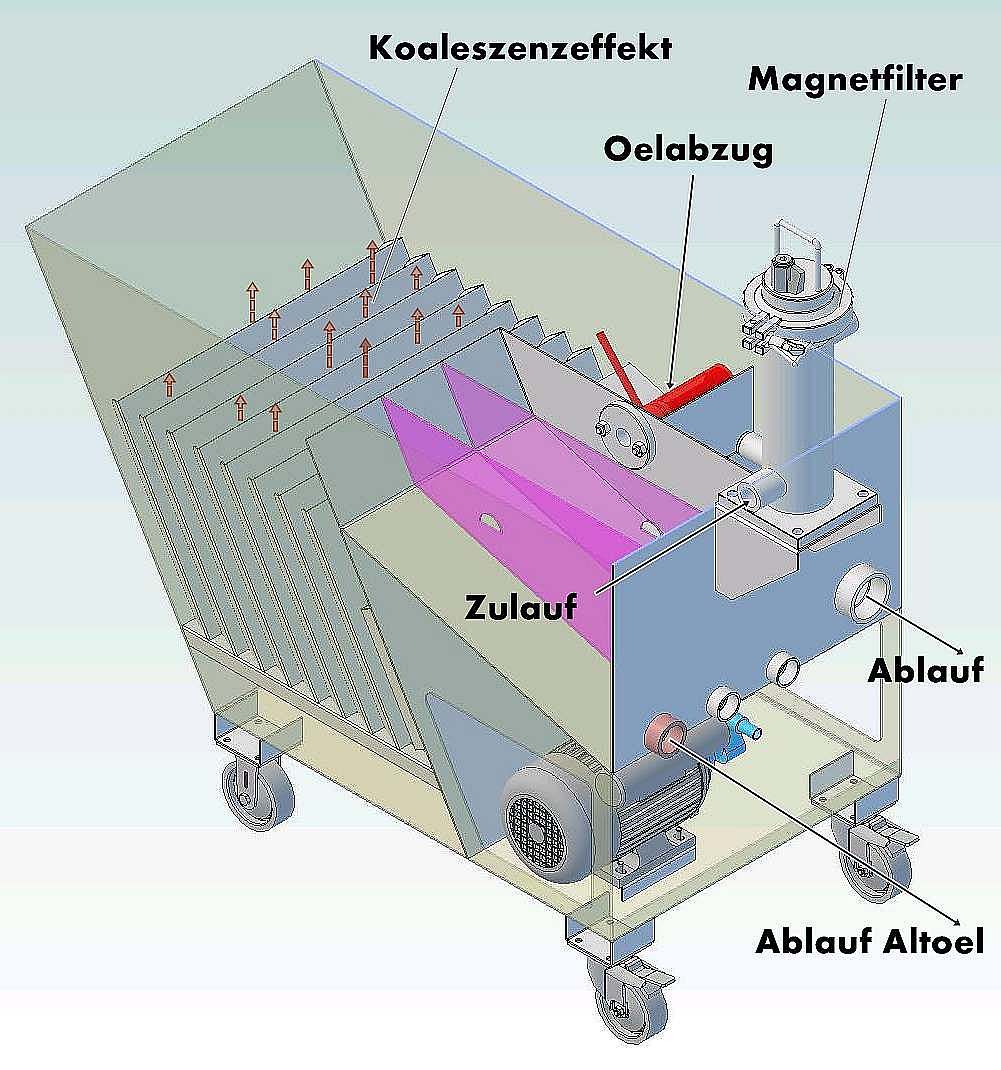

Kühlwasserkreisläufe und Solaranlagen werden aus Frostschutzgründen häufig mit Wasser-Glykol Gemischen gefüllt.

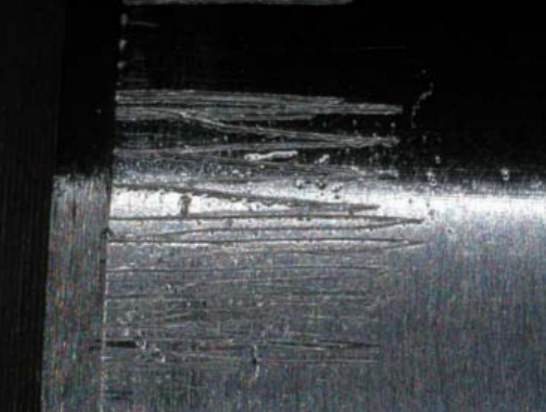

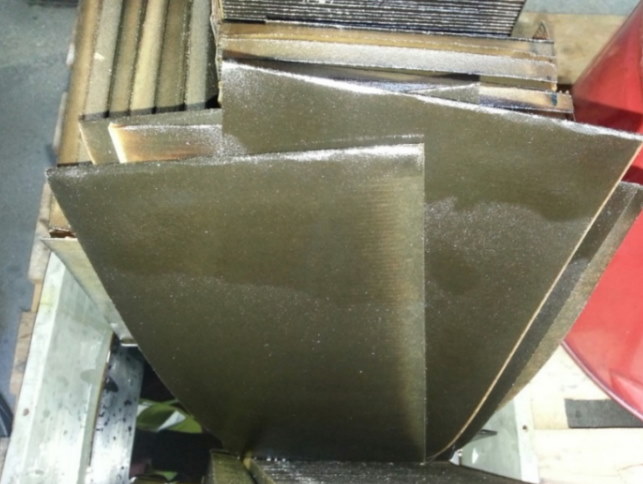

In einem Kaltwalzwerk werden die Walzen zur Bearbeitung des Stahlbandes regelmäßig überdreht und nachgeschliffen, um die Oberflächenqualität des Bandes sicherzustellen.

In Druckgussbetrieben werden die Formen mit hoch temperaturfestem Trennmittel eingesprüht, um ein einwandfreies Entformen der Gussteile zu ermöglichen.

KSS-Prüfung in der Metallverarbeitung. Welche Regeln und Methoden beim Umgang mit Kühlschmiermitteln einzuhalten sind, erfahren Sie hier.

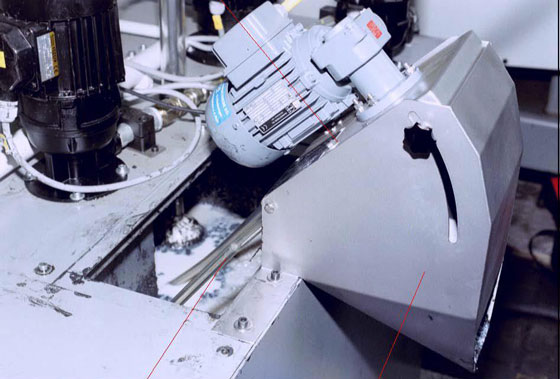

Bei einem Maschinenbauunternehmen werden regelmäßig Gussteile zerspant. Die dabei entstehenden Späne werden durch den Kühlschmierstoff aus der Maschine gespült.

Bei einem Hersteller für Lenkungskomponenten werden die verschiedenen Einzelteile für die Lenkung von PKW mit höchster Präzision geschliffen.

Bei einem großen Hersteller für Getriebe- und Motorenkomponenten ist eine zentrale Emulsionsfilteranlage mit einem Inhalt von ca. 30 m³ Emulsion im Einsatz.

Während des Betriebes der Werkzeugmaschine gelangt Kühlschmierstoff (KSS), Bettbahnöl, Hydrauliköl oder Konservierungsöl in die Emulsion.

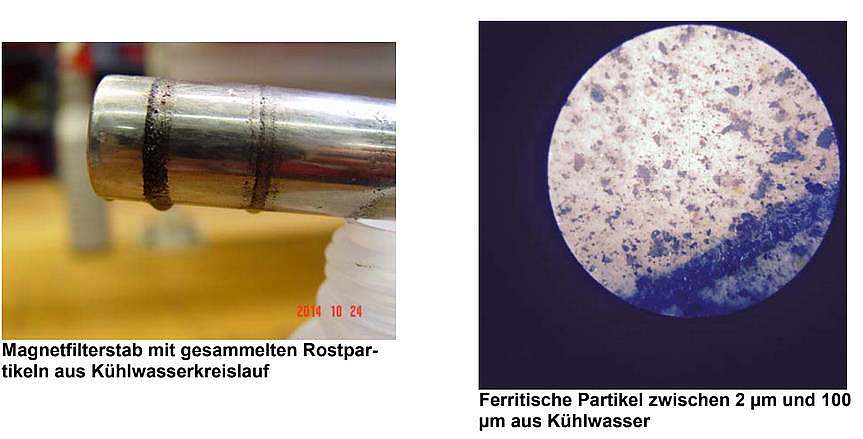

Bei der spanenden Bearbeitung von Graugussteilen entstehen neben groben Spänen feinste Graphit und Eisenpartikel, die als schwarze Schlammschicht auf dem Kühlmittel aufsc

Welche das sind, verraten wir Ihnen gerne!